Core Capabilities

WSTF's Core Capabilities include:

-

Rocket Propulsion Testing and Evaluation

-

Oxygen Systems Testing and Analysis

-

Hypervelocity Impact Testing

-

Propellants and Aerospace Fluids Testing and Analysis

-

Composite Pressure Systems Testing and Analysis

-

Flight Acceptance Standard Testing (FAST)

-

Spaceflight Component Services (SCS)

Click on any image below for more detailed information on our capabilities.

Rocket Propulsion Testing and Evaluation

NASA White Sands Test Facility (WSTF) offers numerous ambient pressure and altitude simulation stands to test rocket propulsion systems, as well as single rocket engines. WSTF has extensive experience testing with hypergolic and liquid oxygen/hydrocarbon propellants over a wide range of operating conditions. WSTF has three test stands that provide simulated altitude greater than 100,000 ft (30,000 m) for engines and engine systems with thrust levels up to 25,000 lbf. Horizontal and vertical firing configurations are available. Two test stands at WSTF support ambient firing at 5000 ft (1500 m) above sea level. Rocket engines with thrust levels up to 60,000 lbf (270 kN) can be tested. Horizontal and vertical firing configurations are available. Propellants available for testing at WSTF include gaseous and liquid hydrogen, gaseous and liquid oxygen, hydrocarbon, hydrazine, Aerozine-50, monomethylhydrazine (MMH), nitrogen tetroxide (N2O4), gaseous and liquid methane, and solid rocket propellants. Propellant saturation and temperature conditioning are available. Pressurants include nitrogen and helium.

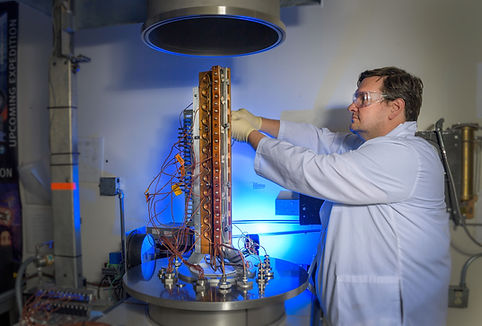

Oxygen Systems Testing and Analysis

The Oxygen Systems Engineering Group specializes in all aspects of the performance and safety of oxygen systems. Through comprehensive analysis, modeling and materials testing in actual environments, WSTF assists in the design and optimization of systems for spacecraft, aircraft, military, and medical applications. Services include materials, components and systems compatibility assessment, systems safety analysis, failure investigation, design assistance, and advanced training in oxygen system buildup, operations, and maintenance.

Hypervelocity Impact Testing

WSTF’s Remote Hypervelocity Test Laboratory is an

access-controlled hazardous test area capable of simulating micrometeoroid and orbital-debris impacts on spacecraft materials and components. Processes allow the safe handling of hazardous (hypergolic, pressurized, or energized) targets or for unique flight hardware.

Composite Pressure Systems Testing and Analysis

WSTF offers leading expertise in the testing, nondestructive evaluation (NDE), and analysis of composite material structures. A damage detection course is offered to train aerospace visual inspectors of flight composite pressure vessels. WSTF performs agelife tests, accelerated aging, hydraulic and pneumatic burst tests, and environmental effects studies on pressurized systems.

Flight Acceptance Standard Testing

Flight Acceptance Standard Testing (FAST) is designed to better understand, improve, and verify the systems, capabilities, and materials used in space flight, and to ensure safety during manned space flights. Materials offgas and outgas. WSTF’s offgas testing identifies and quantifies all gaseous compounds released from a material or article under human habitable atmospheric conditions.

Propellants and Aerospace Fluids Testing and Analysis

WSTF focuses on the safety and performance of hazardous propellant systems including hypergolic fuels and hydrogen. We support on-site propulsion testing as well as remote assistance to end users in aerospace and industry. The WSTF propellants group provides analysis of systems and operational safety, propellant specifications analysis, personal protective equipment assessment, and detection technologies for both industrial and flight applications. A comprehensive materials and components testing capability enables design assistance and problem resolution. WSTF conducts laboratory microanalysis to full-scale field explosion tests. WSTF experts also provide training to the aerospace industry in the safe handling of various propellants.

Spaceflight Component Services

Spaceflight Component Services (SCS) specializes in the handling and processing of spaceflight and flight-like hardware. SCS has clean environment processing facilities ranging from ISO 5 to ISO 7 (Class 100 and 10,000) clean rooms and flow benches, and digital borescope inspection capability. Bonded and controlled spaceflight and critical storage facilities are available with a small team of highly skilled engineers and technicians. Program-qualified personnel have hands-on experience in procedure development, project management, and flight hardware processing, with additional expertise in mono & hypergolic propellant and oxygen systems, and test system design, fabrication, and operation.